Glimt fra stalden

Køerne er meget opmærksomme på hvad der sker omkring dem.

De er ude for at få frisk luft og motionere hver dag, når vejret er til det. Sommeren tilbringer de udenfor og kommer kun indendørs til malkningerne.

I stalden består deres foder af hjemmeavlet kløvergræs-ensilage, wraphø, valset hvede og rug.

Nu står den på malkning.

Narayana har i øjeblikket to landbrugselever, Andrea Topsøe og Peter Lauritsen. Andrea specialiserer sig i økologisk husdyrbrug, og Peter i økologisk planteavl. De hjælper begge til både med jerseykøerne m.v. og i marken i landbruget, og desuden i gartneriet, væksthusene og biavlen. Det giver en meget alsidig uddannelse, både teoretisk og praktisk. Skoleopholdet, som også er en del af uddannelsen til ‘Global Organic Farmer’, foregår på Kalø Økologiske Landbrugsskole indimellem praktikperioderne.

Her er Peter igang med desinfektion inden malkningen. Hygiejne er meget vigtig ved mælkeproduktionen, og kræver fuld opmærksomhed.

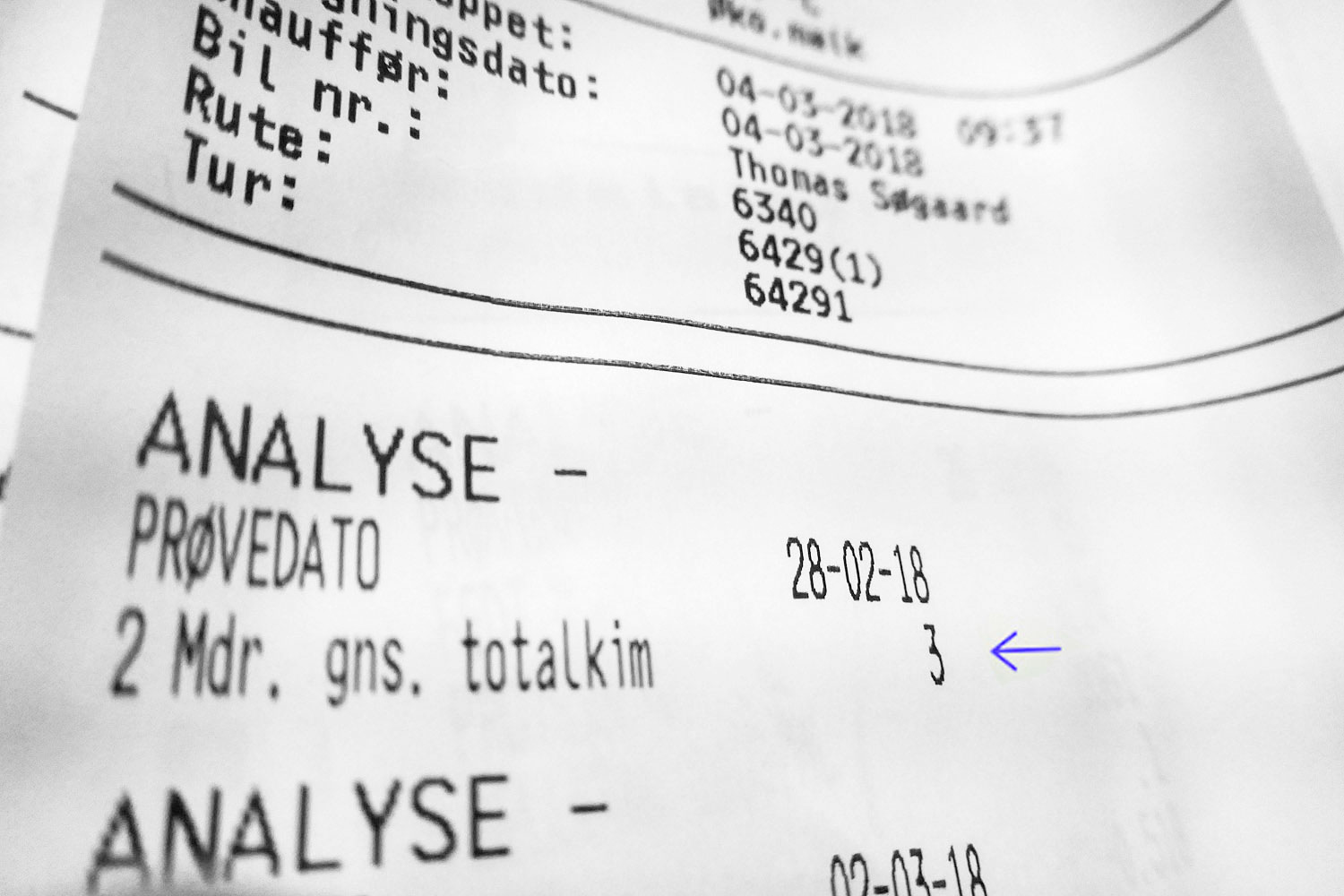

‘Kimtal’ er betegnelsen for antal af bakterier i mælken og bliver regelmæssigt målt og checket.